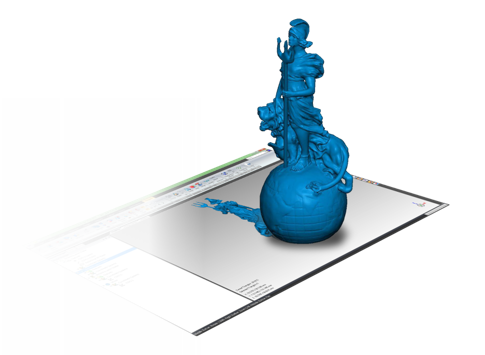

Simufact software solutions allow you to simulate a wide variety of forming and welding processes, as well as metal-based additive manufacturing processes, to optimize manufacturing processes, reduce costs and time to market, while which improves product quality.

Simufact software solutions are divided into three product lines, which have been developed for the specific requirements of each individual process: Simufact Forming, Simufact Welding and Simufact Additive .

In this presentation Technosim will comment a little more about Simufact Welding.

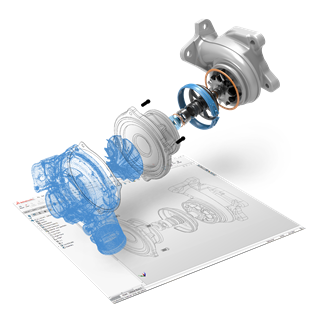

Simufact Welding is a welding simulation tool to define the ideal process parameters, thus avoiding distortions and unwanted welding stresses.

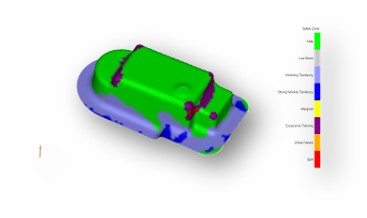

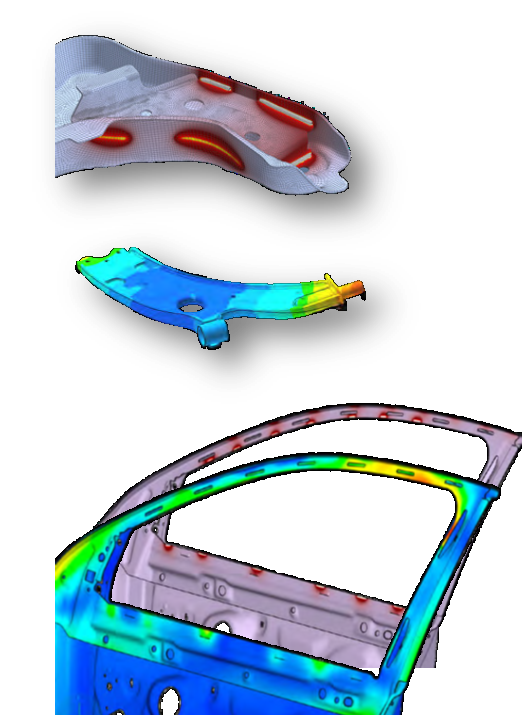

Simufact Welding performs the simulation on the entire material, managing to calculate the different microstructures formed in the area of the material affected by heating, thus predicting possible welding defects, such as thermal cracks and other defects that the process may present.

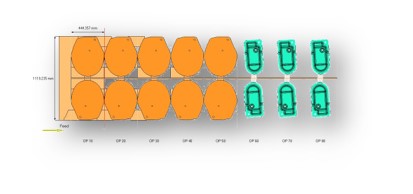

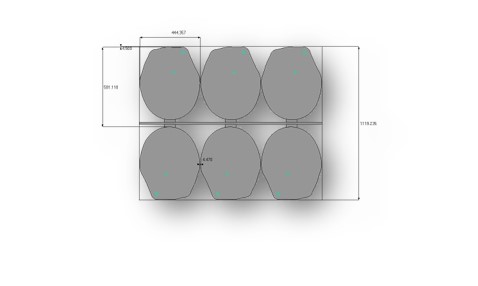

It simulates most joining processes, such as spot welding and Direct Energy Deposition (DED), in addition to having a tool dedicated to evaluating the subsequent process after welding to assess the location and quantity of locking clamps for cooling.

Simufact Welding provides numerous benefits to customers, such as:

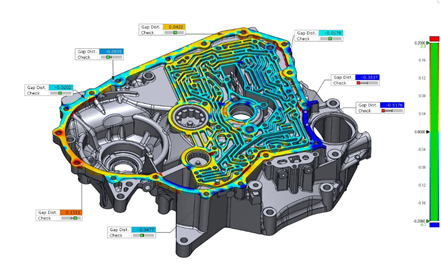

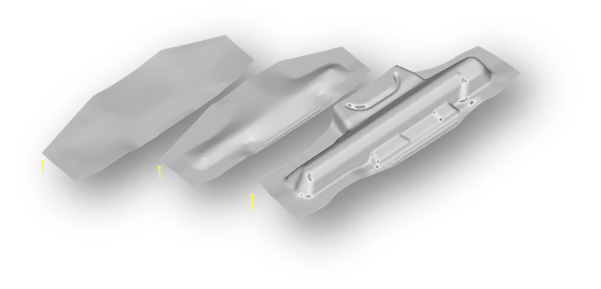

- Identify critical distortions, with regard to assembly characteristics, bulges and gaps;

- Optimize the staples even before finalizing the tools;

- Evaluate the best process for soldering during design;

- Evaluate residual stress and distortion in various scenarios;

- Perform virtual tests / Try Out, eliminating any unnecessary expense with soldering tests;

- Evaluate the influence that heat affects on the metallographic characteristics of the parts, such as hardness and metallic phases;

Examine the behavior of the material in each of the welding stages, thus being able to assess the ideal point of improvement for the process.