Digital Inspection Service for parts and equipment is a quality solution to evaluate, measure and verify the quality of parts and equipment. Using state-of-the-art technology, digital inspection specialists measure the main characteristics of parts and equipment, such as dimensions, shape, surface, tolerances, roughness, etc.

Measurements are performed accurately and quickly, comparing results with specified quality standards and providing detailed reports with the information obtained. The digital inspection service can help companies improve the quality of their parts and equipment , reducing waste and costs and ensuring customer satisfaction.

Inspection in Three-dimensional Metrology

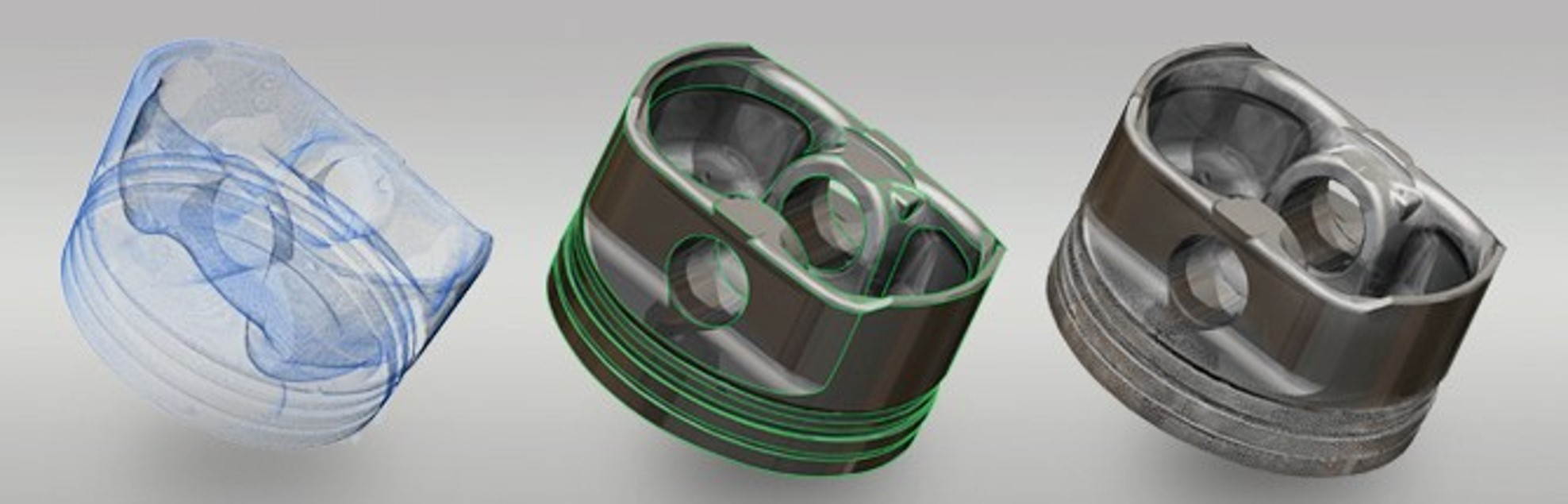

Inspection in Three-Dimensional Metrology is a process used to verify the dimensionality of an object. This technique allows manufacturers to verify the dimensional conformity of their products before they are shipped to the customer.

Inspection in 3D Metrology involves the use of specialized equipment to measure and assess the dimensionality of an object. These devices are usually equipped with digital cameras and sensors to capture the dimensional characteristics of the object. Software is used to analyze these characteristics and compare against design specifications.

One of the main benefits of inspection in 3D Metrology is its accuracy. The equipment used in the inspection is highly accurate and can check even the smallest details of the products. In addition, collected data may be stored for auditing purposes and further analysis.

Another benefit of 3D Metrology inspection is the fact that it can be easily integrated into other production processes. For example, inspection results can be used to adjust machining machine parameters , ensuring that products are manufactured according to quality standards.

Inspection in 3D Metrology can also help manufacturers to reduce costs. By using data collected during inspection, manufacturers can identify and correct problems before they have a significant impact on the cost of production.

Inspection in Three Dimensional Metrology is an essential process to guarantee the quality and dimensionality of products. It allows manufacturers to verify the dimensional compliance of their products and have more control over production costs. Using this technique can help manufacturers improve the quality of their products and reduce production costs .

Digital Inspection with Scanner

The digital inspection service with Scanner is a process that involves high-tech techniques and equipment and allows the inspection of equipment and components quickly and accurately. The scanner is capable of detecting different types of defects, such as cracks, porosity, fissures, wear and other imperfections.

The digital inspection service with Scanner is one of the most advanced, as it makes it possible to identify faults in equipment that cannot be seen with the naked eye, and also to reduce costs, as the scanner is capable of detecting small defects and correcting them. before they get bigger.

Digital inspection with Scanner to study the wear of parts and equipment

We offer a digital inspection service with Scanner to study wear through a fast, accurate and reliable method to study the wear of parts and equipment. Using state-of-the-art 3D scanners, specialized technicians accurately measure the shape, dimensions, areas and other geometric characteristics of parts and equipment.

The collected data is then analyzed to assess wear and tear and, if necessary, to propose action plans to improve the efficiency and safety of the equipment. In addition to inspecting wear and tear, the service can also be used to check the quality of parts and equipment in production, so that they can be adjusted or improved over time.

This inspection approach offers cost-effective benefits as it allows organizations to apply preventive maintenance practices to prevent equipment failures and outages.

Study of springback in metrology

The springback study is a metrology technique used to measure the mechanical strength and elasticity of materials. It is a non-destructive testing technique that can be used to measure the mechanical strength of metallic, plastic, ceramic and other materials. This technique is based on Hooke’s law, which defines the relationship between deformation and applied external force.

The springback study involves the application of a force to the test material, accompanied by a monitoring of the deformation. Strain and force are used to calculate the mechanical strength of the material.

This technique is used as a quick and accurate means of checking the quality of a material, allowing early identification of mechanical defects. As such, it is a widely used method for checking the mechanical strength of metallic, plastic, ceramic and other materials.