Reverse Engineering is an old concept that has not stopped evolving, parallel to the latest technological advances and new industrial practices.

If this is the first time you’re hearing about it and you have no idea how your company can benefit from this technique, it’s worth reading on and checking it out!

Reverse Engineering Services for Companies

The Reverse Engineering Service is used in several sectors, but in most cases, it is used for:

- Create a new part from an existing design;

- Create a new part together with an existing part;

- Understand the competitor’s design;

- Optimize or customize a product.

The reverse engineering service can also be utilized to fully reproduce individual parts.

For example, a team from the University of Oxford has recreated rare and unique musical instruments from the 17th century thanks to Reverse Engineering and 3D printing techniques .

What is Reverse Engineering?

Basically, Reverse Engineering encompasses every process used to understand the functioning of a product, process or system.

For a physical object, Reverse Engineering consists of exploring the way its components were developed and how they contribute to the functioning of the product.

It can also be called Reverse Engineering, which is “taking” a final object to understand it before recreating it from scratch.

It consists of studying an object from its 3D scan in order to understand its manufacturing process or its internal functioning.

It also includes the design of new pieces, thanks to a 3D printer, and thus meeting new needs.

How does Reverse Engineering work?

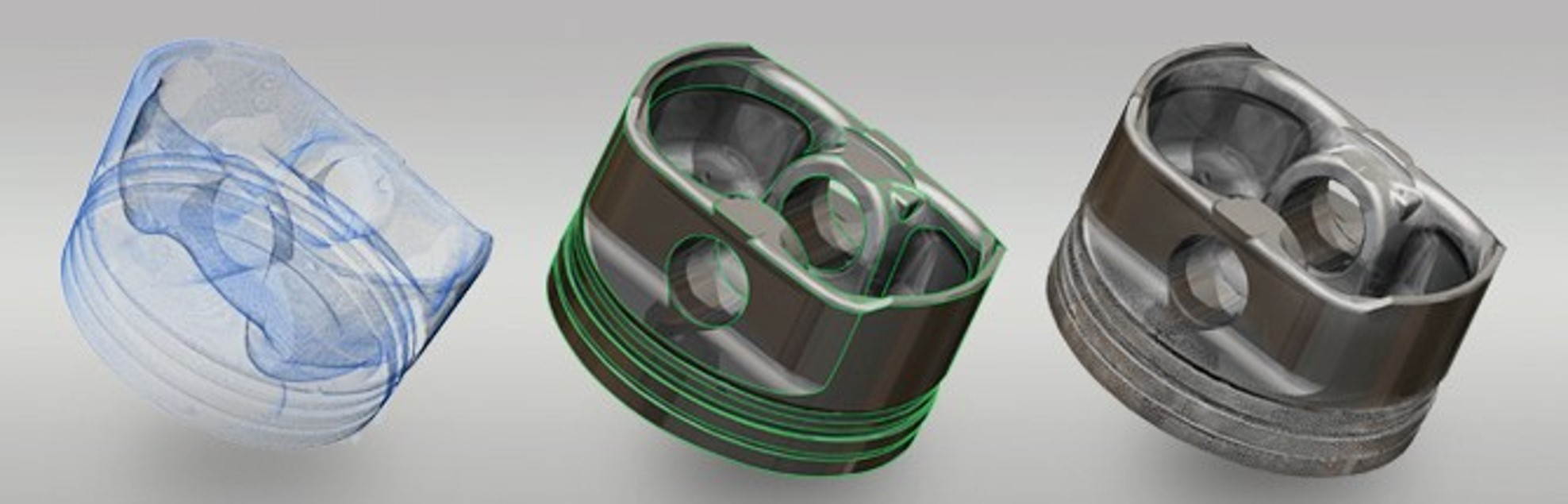

In general, reverse engineering a physical object takes place in three steps:

- Data collection: converting physical geometry into digital data, which is done using tools like a 3D scanner.

- Data processing: to ensure that the digital model faithfully represents the physical object;

- Analysis or rework of the 3D model: after the object has been correctly digitized, it is possible to analyze the 3D model or carry out a rework, either by studying its geometry, making adaptations or creating entirely new parts.

What are the benefits of Reverse Engineering for companies?

One of the main benefits of Reverse Engineering , especially for industries, is the possibility of recovering or optimizing equipment.

Thanks to the digitization of an existing part, it is possible to reproduce the shapes, mold them in software and then create plans for their manufacture.

It is also possible, from the digitization of equipment , to design complementary parts to its operation.

Finally, from a molded object, a second one can be made, identical, but that can also be modified or improved.

What is the impact of Reverse Engineering for organizations?

Reverse Engineering is a powerful tool for organizations, mainly because of such a competitive market.

The ability to derive information from ready-made products is a major advantage over competitors.

Industrial practices are digitizing and moving forward, which makes Reverse Engineering techniques fundamental throughout the product design, development and production process!

Technosim’s differential

Technosim is a company with over 15 years of providing digitization services . We already provide 3D Scanning throughout Brazil and other Latin American countries.

Our differential is that we have great experience in digitizing products and tools from the most diverse areas of the industry.

Technosim is the reference for our customers in equipment and software for 3D scanning.

Main applications of Reverse Engineering

3D Scanning and Modeling can be used in all markets.

Below is a brief description of the types of applications that we usually work with in this process: